Catalyst testing, oxidation, reforming, hydrogenation, dehydrogenation, liquefaction, Fischer Tropsch process, hydro-cracking, carboxylation, catalyst screening, fluid catalytic cracking (FCC), micro reactor system, syngas reactor system, pyrolysis reactor system, packed bed reactor system, vapour rig system, biomass gasification system, hydro-processing catalyst testing system, catalyst-reduction unit, multi-purpose reactor unit, vapor phase reaction system etc.

Trickle Bed Catalytic Reactor

Trickle bed reactors are extensively used in chemical and associated industries such as petroleum, petrochemical, oil and gas, mineral and coal industries, pharmaceuticals, fine and specialty chemicals, biochemicals, and waste treatment. Applications may vary considerably from industry to industry and may include cracking of large organic molecules into useful desired products, upgrading petroleum feedstock, conversion of unsaturated organics into saturated products, conversion of coal-derived products, conversion of gaseous reactants into fuels, hydrodeoxygenation (HDO) of bio-oils (upgrading), polymerization of monomers for a variety of commodity applications, stripping of unwanted chemicals, purification of feedstocks, manufacturing pharmaceutical and their intermediates, aromatization and dearomatization of organic materials used typically in specialty chemicals, oxidation, demetallization, denitrification, dewaxing, desulfurization, removal of pollutants, and wastewater treatment. Trickle bed reactors are preferred for large volume processes. Scales and key operational characteristics of trickle bed reactors used in different applications cover a broad range.

Salient Features

- Trickle Bed Reactor volume from 5cc to 100 litres. Higher volumes optional

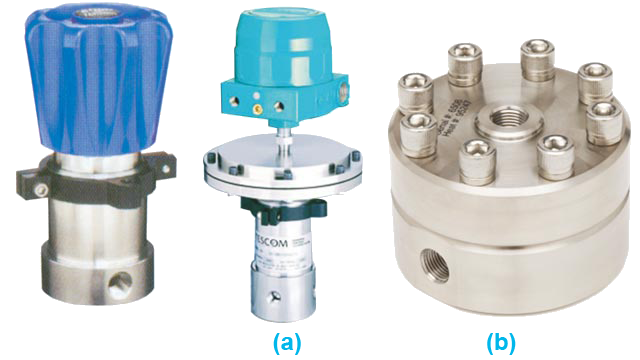

- Designed up to 350 bar & 1200 °C. Higher ratings optional

- Various MOCs such as SS 316, Inconel, Hastelloy etc.

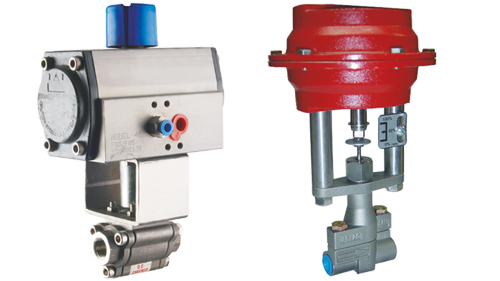

- Explosion proof plants for highly explosive reactions/hazardous area

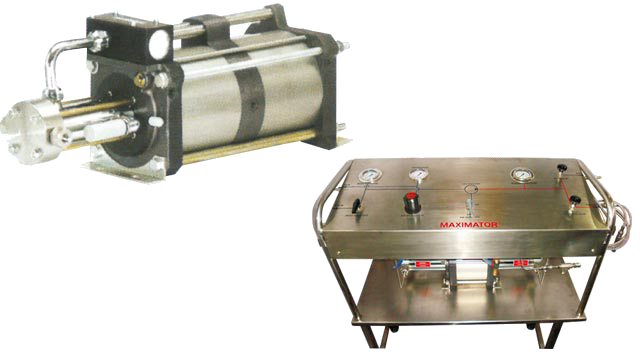

- Table-top or skid mounted plants

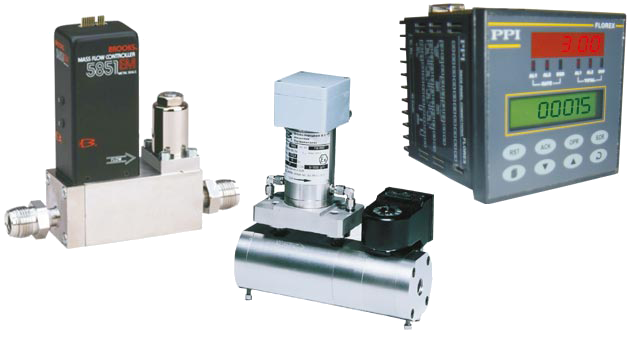

- Either a standard or customisable unit can be offered for gas liquid feed combinations, product outlets, series or parallel reactors, multi zone heating furnaces etc. with integrated controls, high level of safety, automation and SCADA software