| Material of Construction |

SS 316 wetted parts |

SS 316L, Hastelloy C 276, Hastelloy C 22, Hastelloy B, Monel 400, Inconel 600, Inconel 625, Nickel 200, Titanium Gr. 2, Zirconium 702, Tantalum, Tantalum lined |

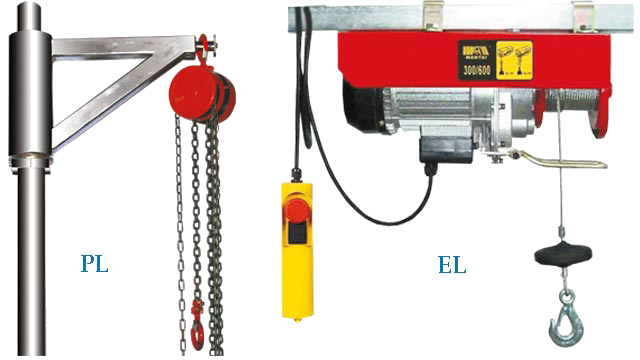

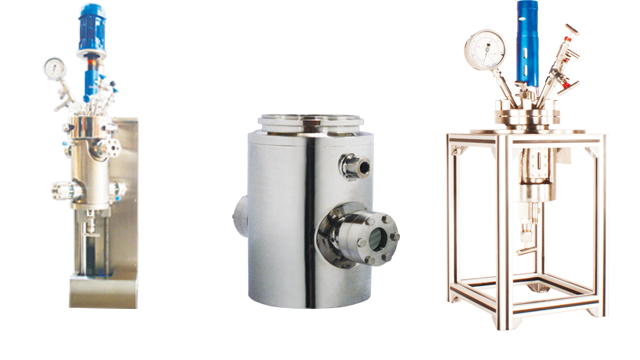

| Head Mounting Style |

Removable head and vessel design |

Fixed head with manual vessel raising lowering (50ml & 750ml)

Fixed head with pneumatic vessel raising lowering (50ml & 2ltr)

Fixed head with manual vessel raising lowering & tilting (50ml & 750ml)

Fixed head with pneumatic vessel raising lowering & tilting (50ml & 2ltr) |

| Heating Type |

Electrical ceramic band heater with cladding & insulation & heater temperature control for 500°C |

Electrical cast ex-proof, IIB + H2 certified

Welded SS 304 jacket with insulation

Welded SS 304 jacket with electrical ceramic heater |

| Motor |

⅛ hp AC motor with 100-1450 RPM(50 ml to 250 ml)

¼ hp AC motor with 100-1450 RPM(500 ml to 2 ltr) |

¼ hp / ½ hp Ex-proof gas group IIB (Zone 1) XB

¼ hp / ½ hp Ex-proof gas group IIC (Zone 1) XC

¼ hp / ½ hp Ex-proof CE ATEX certified II 2G Ex de IIC T4 AZ

¼ hp / ½ hp Ex-proof CSA certified Class 1 Div 2

⅛ hp compact in-line brushless DC motor RPM upto 3000

Gearbox upto 440 rpm |

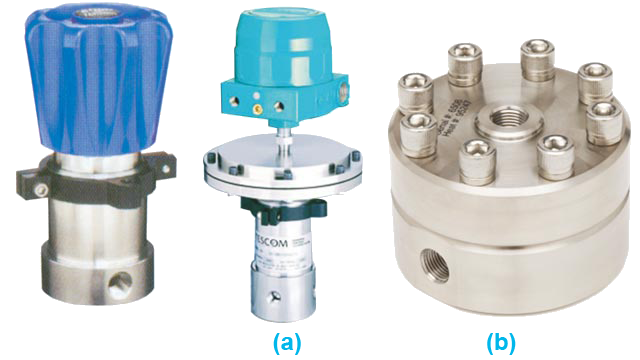

| Shaft Sealing |

Zero leakage magnetic drive coupling:

M8 with 0.8 Nm torque for 50 ml to 250 ml &

M20 with 2 Nm torque for 500 ml to 2 ltr |

Zero leakage magnetic drive coupling:

M20 with 2 Nm (for 50ml to 250ml)

M40 with 4 Nm (for 500ml to 2ltr)

M 80 with 8 Nm (for 500ml to 2ltr)

M120 with 12 Nm (for 1ltr to 2ltr) |

| Stirrer |

4 bladed turbine stirrer (50 ml to 250 ml)

2 stage 6 bladed turbine stirrer(500 ml to 2 ltr) |

Hollow shaft with gas induction Impeller

Anchor (Serpentine cooling coil, max 100 rpm)

Spiral (No cooling coil, max 100 rpm)

Ruston turbine

Paddle

Propeller |

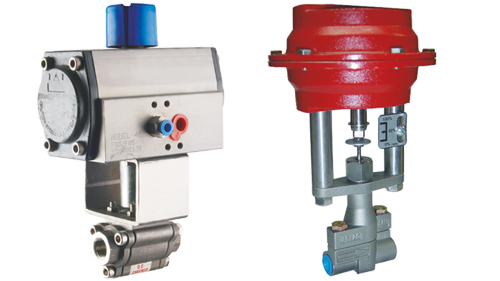

| Standard Nozzles, Valves & Fittings |

External Valves & Fittings:

Pressure gauge, safety rupture disc, gas inlet and liquid sampling needle valve with commondip tube, vent needle valve, solenoid valve at inlet of cooling coil (50 ml to 250 ml)

Internal Fittings:

Serpentine cooling coil (50 ml to 250 ml), Helical cooling coil (500 ml to 2 ltr), dip tube, thermowell with RTD PT100 temperature sensor |

Ball valve powder inlet (¼) with funnel

Flush bottom valve (10 mm)

Baffle (with serpentine cooling coil)

Serpentine cooling coil |

| Gasket |

PTFE up to 300°C |

Metallic grafoil gasket up to 500°C |

| Closure Type |

Split clamp with clamp bolts |

Threaded cap with FKM (viton)'O' ring up to 225°C

Threaded cap with FFKM (valrez) 'O' ring up to 275°C

Split clamp with 'O' ring-FKM (viton) upto 225°C

Split clamp with 'O' ring-FFKM (kalrez) upto 275°C |

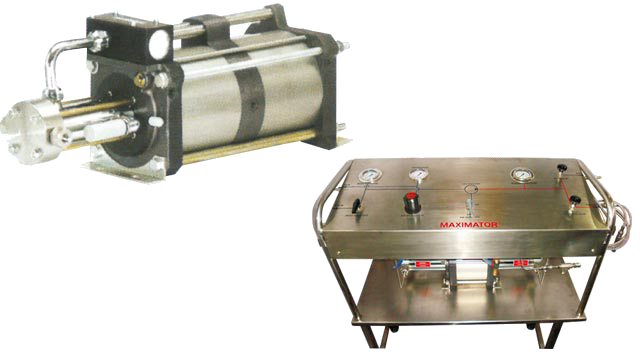

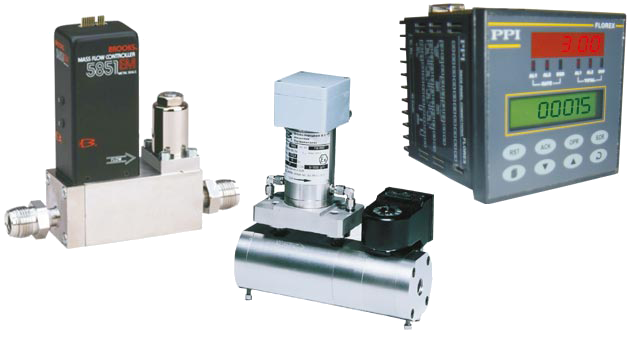

| Control Panel |

SS control panel with programmable PID temperature controller with high temperature alarm and variable frequency drive for motor speed control |

Ex-proof gas group IIA/IIB zone 1 certified

Ex-proof gas group IIC zone 1 certified

Touch screen |

| Power Supply |

1Ø, 220 V AC, 50 / 60 Hz |

Different power supply options may be possible on request |

| Mounting |

SS Table Top (50 ml to 1 ltr)

SS Trolley (2 ltr) |

SS Trolley (50 ml to 1 ltr) |

| Certifications |

By Amar |

Design approval as per ASME code by notified body

CE-PED 2014/68/EU

ASME U stamp coded

ATEX certified reactor 2014/34/EU

CE marked panel & electrical parts

UL/CSA marked panel & electrical parts |