Plasma-Enhanced Chemical Vapor Deposition

PE-CVD SOLUTIONS

Plasma-enhanced chemical vapor deposition (PE-CVD) provides an effective alternative for depositing a variety of thin films at lower temperatures than those used in typical CVD reactors without settling for a lesser film quality. A high-quality silicon dioxide (SiO2) film can be deposited at 300°C to 350°C, while CVD requires temperatures in the range of 650°C to 850°C to produce similar quality films.

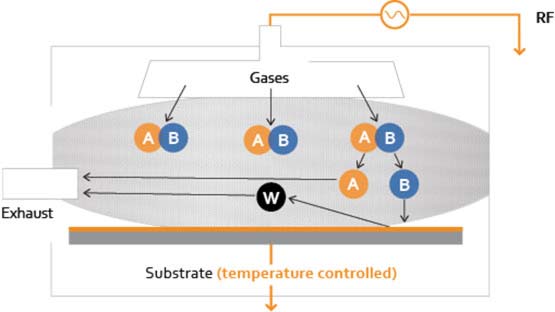

PE-CVD uses electrical energy to generate a glow discharge (plasma) in which the energy is transferred into a gas mixture. This transforms the gas mixture into reactive radicals, ions, neutral atoms and molecules, and other highly excited species. In PE-CVD, the gas phase and surface reactions are strongly controlled by the plasma properties. In place of thermal activation, electron impact dissociation of the gas mixture drives gas phase reactions enabling deposition to be carried out at temperatures much lower than a conventional CVD process. For PE-CVD, deposition rates are usually not a strong function of substrate temperature since surface activation energies are often small. However, film properties such as composition, stress, and morphology are generally strong functions of the substrate temperature.