The system is supplied with a complete educational software package with a wide range of facilities and functions. For most applications the computer is the primary interface between the user and the equipment.

The software displays real-time process mimic diagrams, with readings of the relevant sensor outputs, and controls for the system inputs. The on/off, time proportioned and PID control algorithms are accessible through ‘pop-up’ control boxes, which give the user access to all the key control parameters, including the proportional band, the integral time and the derivative effect.

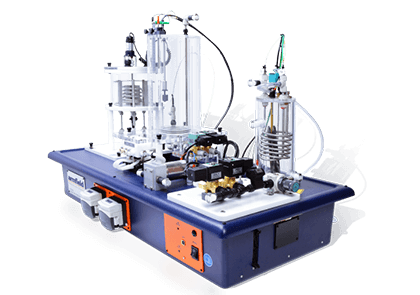

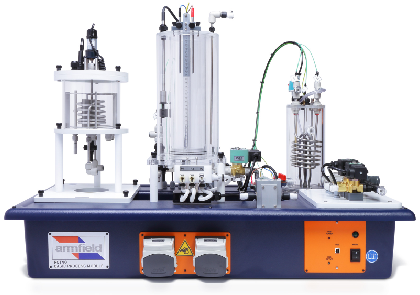

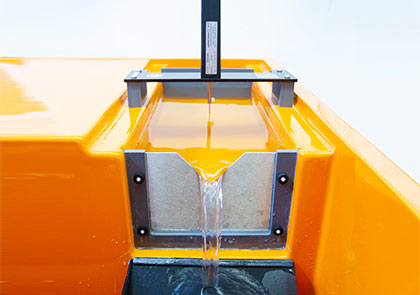

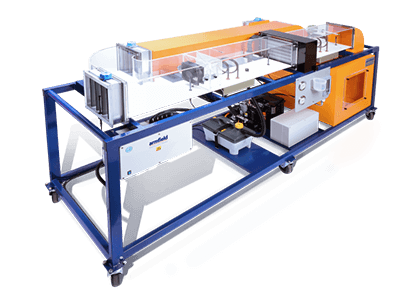

The software is supplied with detailed mimic diagrams, and full instructional help texts for ten predetermined student exercises when using PCT40 and an additional four exercises when using PCT41. These predetermined strategies have been carefully chosen to illustrate a wide range of the system capability and possible control strategies, ie level, flow, temperature, pressure, fluid characteristics, single PID loops, cascade and multiple loops, remote setpoints, etc. However, because of the flexibility of the system, many more control situations are configurable than it is possible to provide predefined student exercises for. Because of this, Armfield have included a user configurable option with the software, which enables the full range of capability from the system to be explored. This is particularly useful for student project work.

Whichever configuration is being used, the software provides powerful data logging and graph plotting facilities, together with sensor calibrations and a wide variety of display and data export options.

The computer communicates to the PCT40 using a standard universal serial bus (USB) interface.

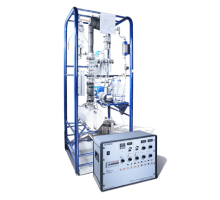

When used with the PCT43, the software also provides a simple SCADA demonstration. The process is controlled using the PID controller in the PCT43, but the P, I & D values can be accessed and varied by the computer, using the RS232 interface. At the same time the status of the process can be displayed on the computer by using the USB interface for data logging only.

Universal Software Interface

For users who wish to write their own software, eg in Matlab or LabVIEW™, full instructions are given for communications with the PCT40 via its built in USB interface. Advanced users are also given the facility to include their own process control algorithm, written in a suitable language such as C++. This is useful for exploring advanced and non-linear control systems.

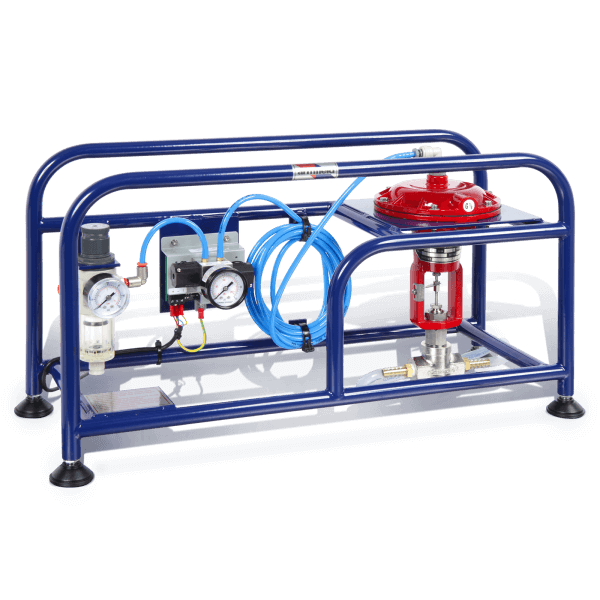

It is possible to control the PCT40/41 loops using external PLC devices or PID controllers. These can be connected directly to the PCT40 for specific configurations. However, with the PCT43 electronic console it becomes very easy to connect up the inputs and outputs to enable a range of loops to be demonstrated.

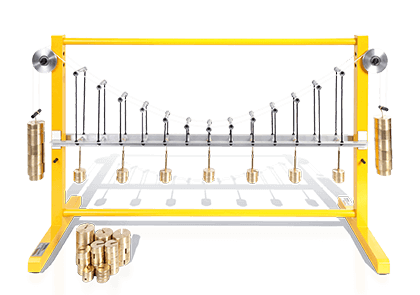

Armfield offer two external units in addition to the PCT43 that can be used for this purpose: